What is Kiln-Dried Heat Treated Lumber?

Kiln-dried heat treated (KDHT) lumber is a type of wood that has undergone a specific drying and treatment process to reduce the moisture content and enhance its durability and stability. This process involves placing the lumber in a specialized kiln where it is subjected to controlled temperatures and humidity levels.

The primary purpose of kiln-drying is to remove excess moisture from the wood, which helps prevent warping, shrinking, and cracking. By reducing the moisture content, kiln-dried heat treated lumber becomes more resistant to decay, insect infestation, and fungal growth.

The heat treatment aspect of this process involves subjecting the lumber to high temperatures for a specific duration. This effectively eliminates any pests or insects that may be present within the wood fibers.

Kiln-dried heat treated lumber is widely used in various construction projects where durability and longevity are essential. It is commonly employed in outdoor structures such as decks, fences, and pergolas due to its ability to withstand harsh weather conditions.

Furthermore, this type of lumber is often preferred for interior applications such as flooring or cabinetry because it reduces the risk of warping or shrinking over time.

The Kiln-Drying Process

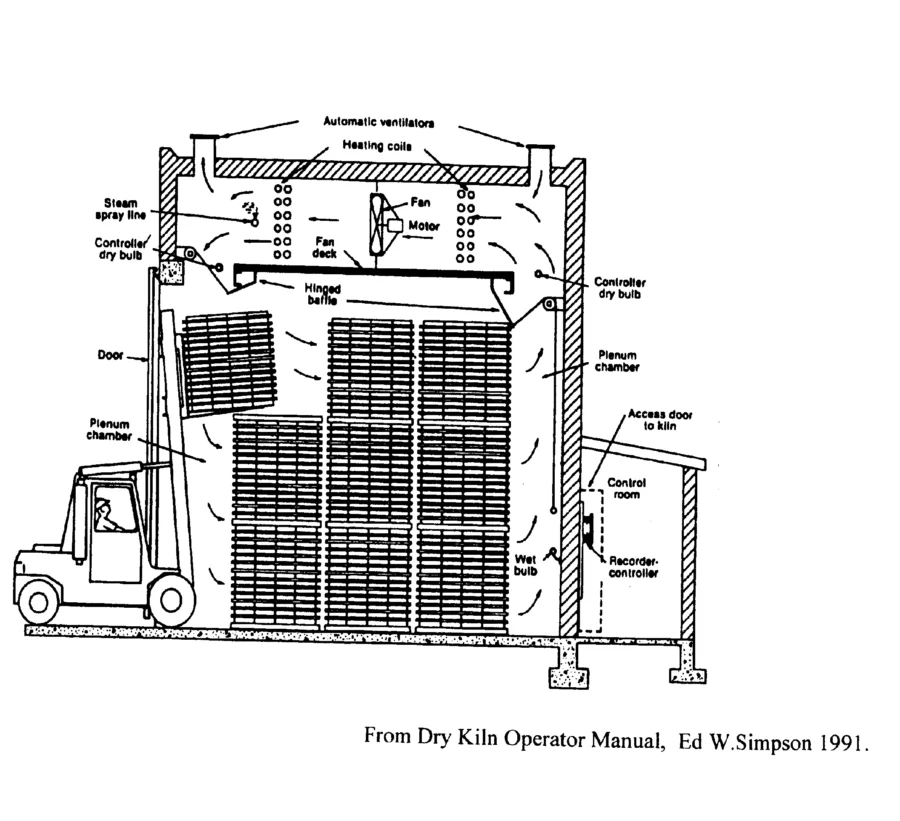

The kiln-drying process plays a crucial role in the production of high-quality lumber and forest products. Pallets of lumber are put into a kiln oven to be put through the drying process.

The temperature is then gradually increased to a specific level that varies depending on the desired outcome. This initial heating phase helps eliminate any moisture present in the wood while preparing it for further treatment.

After reaching the desired temperature, the wood is held at that level for a predetermined period. This allows for proper heat penetration throughout its structure, ensuring consistent results. During this stage, chemical changes occur within the wood fibers that enhance their durability and resistance properties.

Finally, once the required time has elapsed, the temperature is gradually reduced back to room temperature. This cooling phase helps stabilize and set these newly acquired properties within the wood structure.

Lumber that undergoes the kiln-drying process offers numerous benefits over air-dried wood. Firstly, it significantly reduces the moisture content, making it lighter and easier to handle. This makes kiln-dried wood ideal for construction projects where weight is a concern.

Overall, the use of kiln-dried wood ensures a higher level of quality control throughout the production process of forest products. It provides manufacturers with a reliable source of material that meets industry standards for strength, stability, and durability.

Applications of Kiln-Dried Heat Treated Lumber

Kiln-dried heat treated lumber offers a wide range of applications in the realm of forest products.

One of the primary uses of kiln-dried heat treated lumber is in home renovations. It serves as a reliable and sturdy material for framing, flooring, and decking. Its enhanced strength and stability make it ideal for structural components, ensuring long-lasting and safe buildings.

Additionally, kiln-dried heat treated lumber finds its place in the manufacturing industry. It is commonly used for crafting furniture, cabinets, doors, and windows due to its dimensional stability and resistance to warping or shrinking. The high-quality finish achieved with this type of wood adds value to the final product.

Furthermore, this specialized lumber is also utilized in outdoor applications such as fencing, landscaping structures, and exterior cladding. Its resistance to moisture-related issues makes it suitable for enduring various weather conditions without compromising its integrity.

With its versatility and reliability, Kiln-dried heat treated lumber continues to be a valuable asset in the world of forest products.

Choosing the Right Kiln-Dried Heat Treated Lumber

One popular type of kiln-dried wood is Southern Yellow Pine (SYP). SYP is already known for its strength and durability, making it suitable for structural purposes such as framing or decking. It also has a beautiful grain pattern that adds aesthetic appeal to any development.

Cedar is another excellent option when it comes to kiln-dried lumber. Cedar has a natural resistance to decay and insects, making it an ideal choice for outdoor projects like fencing or decking. Its distinct aroma and rich colour make cedar a favourite among developers and builders.

Whether you opt for Southern Yellow Pine (SYP), cedar, or SPF lumber, you can trust that your chosen material will provide strength, stability, and longevity to your project while adding beauty to any space.

Kiln-dried heat treated (KDHT) lumber offers numerous benefits that make it an excellent choice for various construction and woodworking projects. Through the kiln-drying process, this specialized wood achieves enhanced durability, stability, and resistance to warping and shrinking. Its versatility allows it to excel in applications ranging from structural components to outdoor projects, making it a reliable and cost-effective option.

Whether you opt for Southern Yellow Pine (SYP), cedar, or SPF lumber, choosing kiln-dried heat treated wood ensures that the lumber you choose stands the test of time and weather challenges with grace.

If you're searching for dimensional kiln-dried heat treated lumber, reach out to us! Our team of experts will assist you in finding the perfect lumber for your needs.