The Rising Popularity of Mass Timber in the Lumber Industry

The lumber industry has seen a shift towards sustainable and innovative building techniques. In the past decade, Mass Timber has grown in popularity and it has made an impact on the future of concrete and steel.

What is Mass Timber?

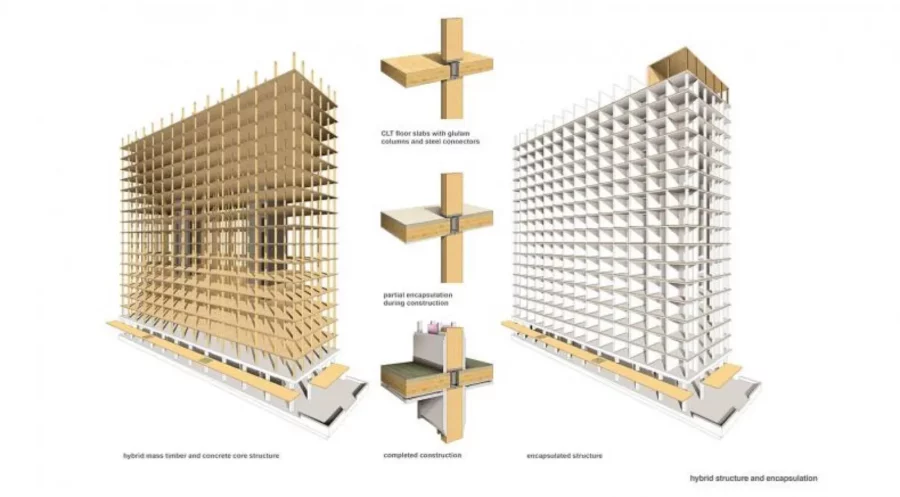

Mass timber is not like ordinary dimensional lumber. it is made of large engineered wood panels that are then compressed, creating a strong, load-bearing building material. There are different types of mass timber products such as cross-laminated timber (CLT), glued laminated timber (glulam), nail-laminated timber (NLT), dowel-laminated timber (DLT), mass plywood panels (MPP), laminated veneer lumber (LVL), parallel strand lumber (PSL), and laminated strand lumber (LSL). Each has its functionality and appearance that make them unique to one another. More on this below.

Understanding Mass Timber

Mass timber is an umbrella term for engineered wood products that comprise large, solid wood panels that are manufactured by stacking multiple layers of lumber boards and gluing or fastening them together. This manufacturing process results in strong and stable building materials suitable for various applications.

There are different types of mass timber products, including:

- Cross-laminated timber (CLT): Composed of layers of lumber boards stacked at right angles, used for walls, floors, and roofs in modern sustainable buildings.

- Laminated strand lumber (LSL): A durable engineered wood product made from strands of wood fiber compressed and bonded together. Commonly used in rim boards, headers, and studs for residential construction.

- Laminated veneer lumber (LVL): An engineered wood product manufactured by layering thin wood veneers and gluing them together. This type of mass timber is ideal for beams, joists, and headers due to its strength and uniformity.

- Nail-laminated timber (NLT): A cost-effective mass timber product made by fastening dimensional lumber with nails. You will see this being used for flooring, roofs, and walls in timber-framed structures and renovations.

- Glue-laminated timber (GLT or glulam): An engineered wood product consisting of multiple layers of dimension lumber bonded together with adhesives. Glulam is commonly used as beams, columns, and arches in various architectural designs.

- Parallel strand lumber (PSL): An engineered wood product made from long strands of wood aligned in parallel and bonded together. You typically install these as load-bearing columns, beams, and poles in heavy construction projects.

- Dowel-laminated timber (DLT): A structural wood product created by aligning and fastening dimension lumber with hardwood dowels. This is best used in walls and ceilings for its aesthetic appeal and load-bearing capabilities.

Is Mass Timber Better Than Concrete or Steel?

while concrete and steel remain a popular building material, mass timber presents a compelling alternative with advantages in sustainability, structural performance, design flexibility, and construction efficiency. The debate surrounding mass timber versus traditional building materials like concrete and steel hinges on several key factors:

Environmental Impact

One of the key drivers behind the rising popularity of mass timber is its environmental performance. Unlike concrete and steel, the production of mass timber generates significantly lower carbon emissions, making it more sustainable. The carbon dioxide captured by trees during their growth is then stored within the mass timber products, acting as a carbon sink and helping mitigate climate change. According to UNECE, opting for wood could cut emissions by 150 million tCO2e annually, while storing an extra 0.52 billion tCO2e in buildings.

Mass timber is sourced from responsibly managed forests, promoting sustainable forestry practices and supporting global reforestation efforts. As consumers increasingly prioritize eco-friendly alternatives, mass timber is the choice for environmentally conscious buildings.

Structural Performance

Despite many misconceptions, mass timber demonstrates impressive strength and load-bearing capacity. Advances in engineering allow for innovative designs while remaining lightweight compared to concrete and steel. Mass timber has incredible structural efficiency, allowing architects and engineers to design innovative and daring designs with reduced material usage.

Design Flexibility

Mass timber offers flexibility in creating aesthetically pleasing structures. Its versatility allows for a wide range of architectural styles and concepts, from modernist buildings to rustic cabins. Something you cannot get from concrete and steel.

Moreover, the aesthetic appeal of exposed wood in modern architectural designs has played a significant role in the material's popularity. The warm and natural appearance of mass timber provides a sense of harmony with the surrounding environment. Even Paris is opting to use Mass Timber for their Olympic Stadiums.

Construction Efficiency

Prefabricated mass timber components streamline construction processes, reducing time and labour costs. The lightweight nature of mass timber enables faster assembly and minimizes delays.

Is Mass Timber Fireproof?

Mass timber actually has great fire-resistant properties. The thick cross-section of CLT and glulam, combined with the wood's inherent charring behaviour, creates a protective layer that insulates the core during a fire. Combined with appropriate fire-resistant coatings and building design strategies, mass timber buildings can meet and even exceed fire safety standards.

What are the Disadvantages of Mass Timber?

While mass timber offers numerous benefits, there are some potential drawbacks:

- Fire Risk:

- Despite its fire-resistant properties, mass timber is still at risk of fire damage, especially during construction. Adequate fire safety measures and building regulations must be implemented to mitigate this risk effectively.

- Moisture Sensitivity:

- Mass timber can be vulnerable to moisture absorption, which may lead to dimensional changes, decay, and mold growth if not properly protected. Proper design, detailing, and maintenance are important to prevent moisture-related issues.

- Limited Availability:

- Compared to concrete and steel, mass timber may have limited availability in certain regions. This could impact project timelines and procurement costs, necessitating careful planning and coordination.

- Acoustic Performance:

- Mass timber structures may exhibit lower acoustic insulation compared to concrete or steel buildings. Incorporating sound-absorbing materials or acoustic treatments may be required to achieve desired noise reduction levels.

Despite these downsides, ongoing research, technological advancements, and industry expertise are tackling these issues, making mass timber an increasingly viable option for sustainable and innovative construction projects.

The increase in popularity of mass timber in the construction industry is undoubtedly a result of its numerous advantages. From its carbon sink abilities to its structural efficiency and fire-resistant properties, mass timber continues to revolutionize the construction sector. As awareness about sustainable building practices grows and innovative designs gain traction, mass timber is poised to remain a cornerstone of modern architecture and sustainable development.

If you are searching for mass timber for your project, contact us today. www.olympicind.com/contact/