A Guide to Softwood Lumber Grades

From A Select to No. 3: Understanding Softwood Lumber Grades in Construction

The grade of lumber you choose can make a huge difference in the strength and durability of your final structure. But with so many different grades available, how do you know which one is right for you?

Recognizing that our exploration only scratches the surface of this topic, there is a whole catalog of lumber grades to choose from. Stay tuned for more in-depth blogs dedicated to each specific grade type.

What Are Lumber Grades?

Lumber grades play a crucial role in determining the quality and suitability of wood for different applications. These grades categorize lumber based on defects, appearance, and durability. Understanding them is essential for selecting the right material and ensuring consistent performance in construction projects.

The Importance of Lumber Grading in Construction

By adhering to lumber grading guidelines, builders and contractors can select the right materials for various applications, such as sheathing, paneling, or kitchen cabinets.

Graded lumber provides a standardized measure of quality and performance, while also optimizing usable material yield and minimizing waste. Additionally, complying with building codes and regulations is important, and following the appropriate lumber grade helps achieve this.

How is Softwood Lumber Graded?

Lumber grading involves assessing appearance, strength, and intended use. Each grade has specific requirements for size, surface finish, and defects like knots. Lumber undergoes either visual inspection or machine grading, classifying each piece according to established standards. They measure the number and size of knots, check for straightness, and assess the overall appearance to assign a specific grade to each piece of lumber.

This grading process ensures transparency and reliability in the lumber industry, providing builders and contractors with a standard measure of quality and performance. By adhering to established standards, the grading process helps optimize usable material yield and ensures compliance with building codes and regulations. The grades are determined by the size and number of clear pieces that can be obtained from a board when it is cut up to be used to make a product. This ensures that the lumber meets specific requirements for clear sections and defines defects.

An illustrated guide is available to help understand different grades of lumber.

Select Appearance Lumber Grades

Select grades, otherwise known as appearance grades, offer visually appealing and high-quality lumber. This is the type of lumber used for tables or high-end flooring applications. These grades provide clear face cuttings with minimal defects or blemishes, ensuring a uniform appearance, straight grain, and consistent color.

With exceptional aesthetics and premium performance, select appearance lumber grades enhance the overall visual appeal of any project. Whether it's for strip flooring, kitchen cabinets, paneling, or even siding, these grades guarantee a stunning finish. Experience the beauty and quality of select appearance lumber grades for your next woodworking or construction project.

A Select

A select appearance grade represents the highest grade of lumber available. It is often used in prestigious projects where only the best will do. This grade provides clear cuttings with no defects, knots, or imperfections.

The wood has a pristine appearance, excellent structural properties, and exceptional durability. A select appearance grade guarantees an exquisite finish and long-lasting performance.

B Select

B Select is a high-quality lumber grade commonly used for finishing work. This grade of lumber is known for its lack of knots and imperfections, making it ideal for projects that require a pristine appearance. While B Select lumber may be more expensive than lower grades, the investment is often worth it for certain projects.

C Select

C Select is a premium lumber grade that is highly sought after for its superior quality and lack of visible defects. This high-quality grade is commonly used in fine woodworking and cabinetry projects, where aesthetic appeal is paramount.

D Select

D Select is the epitome of appearance lumber grades. With a flawless surface and no visible defects or knots, it's the pinnacle of quality. This grade of lumber finds its place in high-end furniture, intricate trim work, and stunning architectural details.

Non-Stress Lumber Grades

Structural lumber grades are used for building and construction purposes, like framing homes or building decks. Appearance lumber grades, on the other hand, are important for projects where the wood's appearance matters, such as furniture or cabinetry.

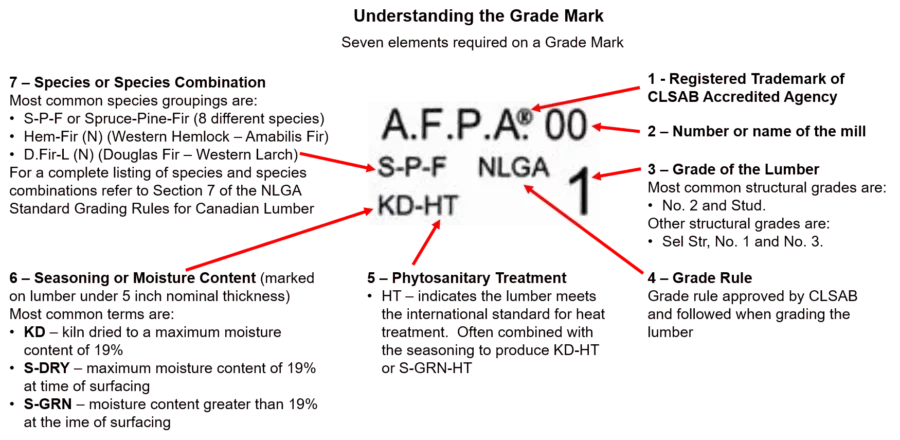

Remember to look for grade stamps on the lumber to ensure you're purchasing the correct grade for your project.

No. 1 (Construction) Grade Lumber

No. 1 lumber, the highest common grade of softwood lumber, has fewer defects and knots compared to lower grades. No.1 & BTR (Better) lumber is slightly lower in grade but still considered high quality. Both No. 1 and No. 1 & BTR lumber are used for high-end construction projects and for trusses, lintels, rafters, and joists.

No. 2 (Standard) Grade Lumber

No. 2 lumber is commonly used for general construction purposes. It may contain tight knots that do not affect the wood's strength. While it may have some imperfections like warping or twisting, it can still be used effectively. This grade of lumber is a cost-effective option for projects that don't require a high-quality finish.

No. 3 (Utility) Grade Lumber

No. 3 Utility Grade lumber, the lowest grade available, has numerous knots, splits, and defects. However, it can still be used for non-structural projects like crates or pallets. Careful inspection and selection are crucial as defects can impact its strength and durability.

No.4 (Economy) Lumber

Economy grade lumber, is commonly used in construction. It is ideal for non-structural purposes such as building temporary structures, plywood or pallets.

Stress Graded Lumber

This type of lumber is also known as dimensional lumber like 2" x 4". Dimensional lumber serves its purpose in a range of structural applications, including posts, beams, flooring, joists, studs, and other scenarios requiring weight-bearing (stress) capacity.

Stress Graded Lumber is classified based on several factors including strength, stiffness, and uniformity. The grades include:

- Structural Light Framing

- Light Framing

- Studs

- Structural Joists and Planks

Conclusion

Our team of lumber traders can guide you through the grading process and help you make an informed decision. So, whether you need No. 1 & BTR lumber, No. 2 lumber, or any other grade, get in touch with Olympic Industries today and let us source the lumber you need for your developments.